- Home

- MIM Materials

MIM Materials

Common Metal Materials for Metal Injection Molding

Hard Alloy Materials

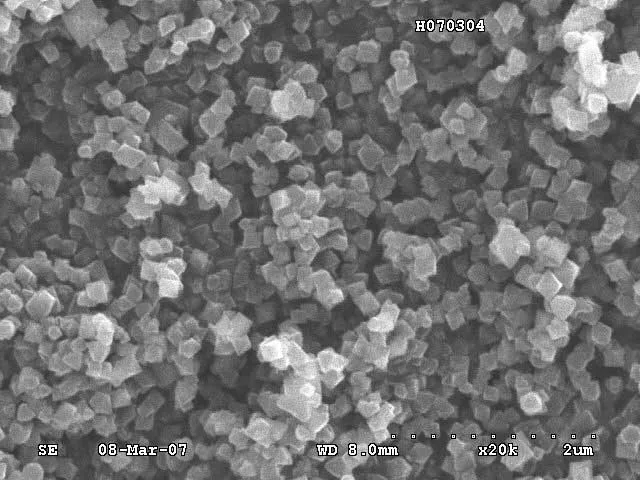

Powder metallurgy hard alloy materials primarily consist of refractory metal carbides or carbonitrides. Due to their outstanding combination of strength, hardness, and toughness, hard alloys find extensive applications in cutting tools, mining equipment, wear-resistant components, and more.

These applications span various manufacturing sectors such as steel, automotive, aerospace, CNC machining, mechanical molds, marine engineering equipment, rail transportation equipment, electronic information technology, engineering machinery, as well as industries like mining, oil and gas extraction, and infrastructure construction.

Magnetic Materials

Magnetic metal materials can be categorized into two main types: powder metallurgy permanent magnetic materials and soft magnetic materials. Permanent magnetic materials include samarium-cobalt rare-earth magnets, neodymium iron boron magnets, sintered aluminum-nickel-cobalt magnets, and ferrite magnets.

Powder metallurgy soft magnetic materials are primarily composed of soft magnetic ferrites and soft magnetic composite materials. The advantage of using powder metallurgy to produce magnetic materials lies in its ability to create magnetic particles within a single-domain size range, achieve consistent particle orientation, and directly manufacture high energy product magnets close to their final shapes. This is particularly advantageous for hard and brittle magnetic materials, especially those difficult to process.

Metal Material Range

The metal materials for MIM is applicable to a wide range of materials, including low alloy steels, stainless steels, tool steels, nickel-based alloys, tungsten alloys, tungsten carbides, titanium alloys, magnetic materials, KOVAR alloys, and so on.

Metal Materials and their areas of application

| Material Classification | Material Grade | Application Areas |

|---|---|---|

| Iron-based Alloys | Fe-2Ni,Fe-8Ni 310 | Various structural components in automotive, machinery, etc. |

| Stainless Steel | 316L,17-4PH,420,440C | Medical devices, watch components |

| Hard Alloy | WC-Co | Various tools, clocks, watches |

| Ceramics | A1 203,ZrO2,SiO2 | IT electronics, daily necessities, watches |

| Heavy Alloys | W-Ni-Fe,W-Ni-Cu,W-Cu | Communication, daily goods |

| Titanium Alloys | Ti,Ti-6Al-4V | Medical, aerospace |

| Magnetic Materials | Fe, Fe50Ni, Fe-Si | Various magnetic components |

| Tool Steel | 42CrMo4,M2 | Various tools |

Properties of Typical Metal Materials

| Material Classification | Material Grade | Application Areas |

|---|---|---|

| Iron-based Alloys | Fe-2Ni,Fe-8Ni 310 | Various structural components in automotive, machinery, etc. |

| Stainless Steel | 316L,17-4PH,420,440C | Medical devices, watch components |

| Hard Alloy | WC-Co | Various tools, clocks, watches |

| Ceramics | A1 203,ZrO2,SiO2 | IT electronics, daily necessities, watches |

| Heavy Alloys | W-Ni-Fe,W-Ni-Cu,W-Cu | Communication, daily goods |

| Titanium Alloys | Ti,Ti-6A1-4V | Medical, aerospace |

| Magnetic Materials | Fe, Fe50Ni, Fe-Si | Various magnetic components |

| Tool Steel | 42CrMo4,M2 | Various tools |