JXMIM - Professional Metal Injection Molding manufacturer

13+ Years in complex metal parts manufacturing, quote in 3 hours, rapid prototyping in 5-8 days, and mass quantity can be delivered in 12 working days!

Professional Metal Injection Molding manufacturer

13+ Years in complex metal parts manufacturing, quote in 3 hours, rapid prototyping in 5-8 days, and mass quantity can be delivered in 12 working days!

Years of Experience

Parts Shipped Annually

Workshop Area

JXMIM is committed to solving the problem of precision and complex metal parts manufacturing for medical, communication, automotive, industrial, and consumer products areas. We utilize an advanced and cost-effective technology “Metal Injection Molding ” to make sintered metal parts. And cooperate with Shanbo to provide more comprehensive metal parts solutions.

One-stop Solutions

Material Customization

Metal Injection Molding

As a high-tech enterprise, JXMIM has more than 13 years of metal injection molding experience for complex sintered metal.

Equipped with more than 20 metal injection molding machines, working in 2 shifts, we provide you with high-efficiency services, rapid molding will be delivered within as soon as 5 days.

Mold Tooling & Design

Surface Treatment

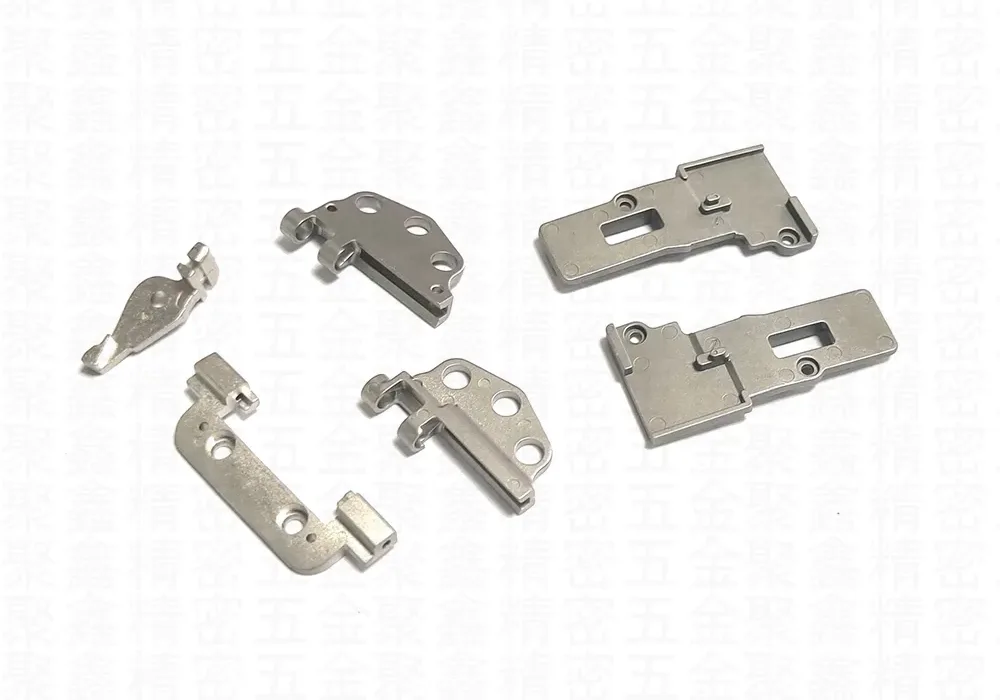

Recent Projects

Our Advantages

Quality driven

Fast Delivery

Feeding Tech

Oncall Service

Get An Instant Quote!

Quick within 3 hours · Rapid molding in 5-8 days

Testimonials

Joseph

Mechanical Engineer - Power Equipment Company

“JXMIM has been our long-term partner. Their MIM technology and quality enable us to efficiently produce the complex components required for medical equipment, while the service is very thorough. Trustworthy!”

Dr. Charlotte

Director Manager - Medical Device Manufacturer

Charles

Supply Chain Director - Automotive Technology

Order steps

It’s easy to work with us