- Home

- MIM Manufacturing Equipment

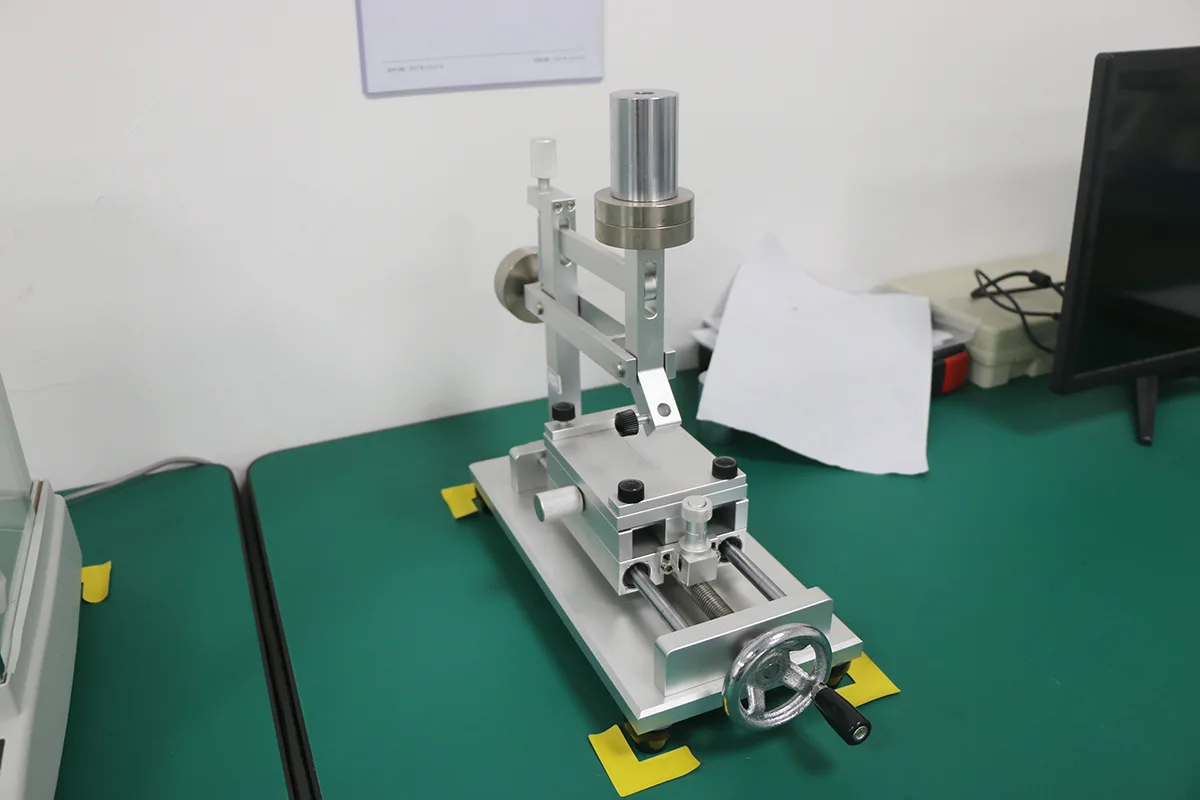

MIM Manufacturing Equipment

Our Maintaining procedures

Calibration Verification

Regularly calibrate and verify the accuracy of equipment settings to ensure precise control over the injection molding process.

Cleaning and Lubrication

Keep all machinery components clean from contaminants and apply appropriate lubrication to reduce friction and prevent wear.

Tooling Maintenance

Regularly inspect and maintain the molds and tooling to ensure they are in optimal condition, addressing any signs of wear or damage promptly.

Monitoring Fluid Levels

Monitor hydraulic fluid, coolant, and other fluid levels, ensuring they are at the recommended levels for efficient and safe operation.

Temperature Control

Calibrate and maintain temperature control systems to guarantee consistent and accurate heating for the metal injection process.

Training for Operators

Provide comprehensive training to equipment operators to ensure they understand the machinery, its capabilities, and are capable of identifying early signs of issues.

Predictive Maintenance

Implement predictive maintenance, with monitoring equipment performance data and utilizing sensors, to anticipate and address potential problems before they escalate.

Emergency Response Plan

Develop a robust emergency response plan to address any unexpected breakdowns promptly, minimizing downtime and ensuring a swift resolution.