- Home

- Quality Control

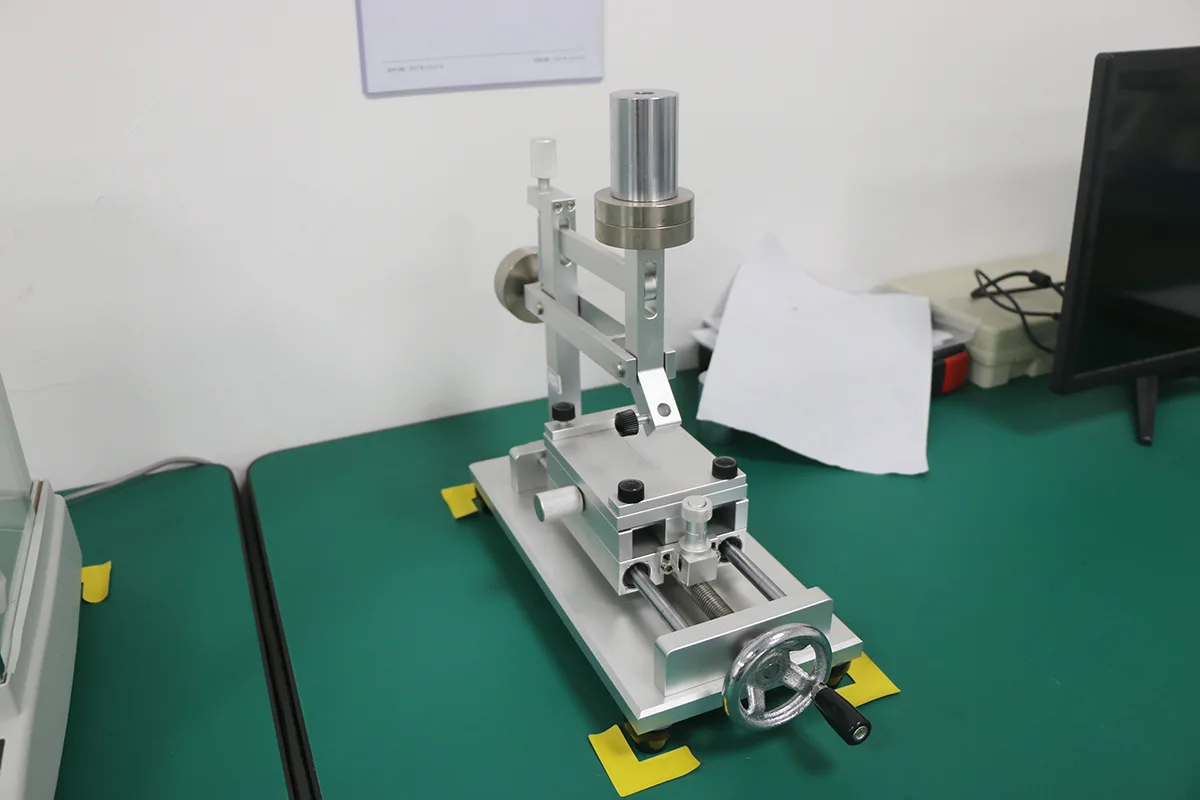

Quality Control

Quality process

2. Feeding Technology

Cemented carbide powder requires a suitable binder when mixing. JXMIM fully mixes the cemented carbide powder and the binder during mixing and strictly controls the process temperature to avoid volatilization and uneven distribution of the binder. The mixed materials have good rheological properties and viscosity values after being fed.

3. Forming

The key link in the production of JXMIM cemented carbide parts. By reasonably controlling the mold temperature, feeding amount, injection pressure, holding pressure, holding time, injection speed, etc. during the injection process, we will effectively avoid injection production. The generation of blank defects.

4. Degreasing

JXMIM considers the need for degreasing during the mold design stage, and ensures that the degreasing agent can fully enter every corner of the part through reasonable mold design. We strictly control the degreasing time and temperature, use a step-by-step temperature rise method for degreasing, control the concentration and frequency of use of the degreasing agent, and conduct regular inspections of degreasing equipment and process parameters.

5. Sintering

The density of cemented carbide is high, and the product is prone to deformation due to its own gravity during liquid phase sintering. JXMIM uses appropriate support devices and selects materials with comparable shrinkage rates as support plates for larger products, while minimizing the liquid phase sintering time to achieve the ideal sintering effect.

Common defects and solutions

Solution: JXMIM takes measures such as improving material fluidity or changing materials, increasing wall thickness, raising mold temperature, increasing injection pressure, and extending injection time to solve the problem of insufficient injection.

Solution: JXMIM prevents weld marks by taking measures such as increasing injection pressure, accelerating injection speed, increasing material temperature and mold temperature, and appropriately reducing shunting.

During the injection process, the air in the mold cavity has no time to be discharged and is trapped by the material or compressed to the inner wall of the mold to form air pockets, causing under-injection on the surface of the product and affecting the appearance quality and even mechanical strength of the product.

Solution: JXMIM takes measures such as improving material fluidity or changing materials, increasing wall thickness, raising mold temperature, increasing injection pressure, and extending injection time to solve the problem of insufficient injection.

Deformation refers to the bending or distortion of the molded product after cooling, which directly affects the appearance and dimensional accuracy of the product, and even causes the product to be scrapped.

Solution: JXMIM takes measures such as improving material fluidity or changing materials, increasing wall thickness, raising mold temperature, increasing injection pressure, and extending injection time to solve the problem of insufficient injection.

quality certificates

If you have any questions please let us know

You will get our response very soon